Maintenance Notice (10:30 PM June 7 - 2:00 AM June 8, 2025 UTC): This website is scheduled to be unavailable due to maintenance. We appreciate your patience and understanding.

Product Document Searching Made Easy by 2D Code! | TCI Chemistry News June 2025 | [Product Highlights] Benzoquinone Derivative Useful for... | Various analytical charts can be searched on each product detail page and Product Document Search (The kinds of analytical charts differ by product)

Maximum quantity allowed is 999

Please select the quantity

Fabrication and Evaluation of Organic Field-Effect Transistors (OFETs) : Fullerene C70

Fullerene C70 (purified by sublimation)

[for organic electronics]

Fullerene C70

CAS RN: 115383-22-7

Product Number: F1233

Performances of C70 [F1233]-based OFETs

![Performances of C70 [F1233]-based OFETs](/assets/cms-images/F1233-device-method-structure-en.png)

Table. OFETs Characteristics of Fullerene C70 [F1233]-based OFETs

| Entry | Fabrication Method | Device Configuration | SAM Treatment | Tsub(°C) | Polarity | μ (cm2 V−1 s−1) | Vth (V) | Ion/Ioff |

|---|---|---|---|---|---|---|---|---|

| Entry1 | Fabrication MethodVacuum deposition | Device ConfigurationTCBG | SAM TreatmentHMDS | Tsub(°C)RT | Polarityn | μ (cm2 V−1 s−1)0.52 | Vth (V)6.7 | Ion/Ioff106 |

| Entry2 | Fabrication MethodVacuum deposition | Device ConfigurationTCBG | SAM TreatmentOTS | Tsub(°C)RT | Polarityn | μ (cm2 V−1 s−1)0.55 | Vth (V)8.3 | Ion/Ioff106 |

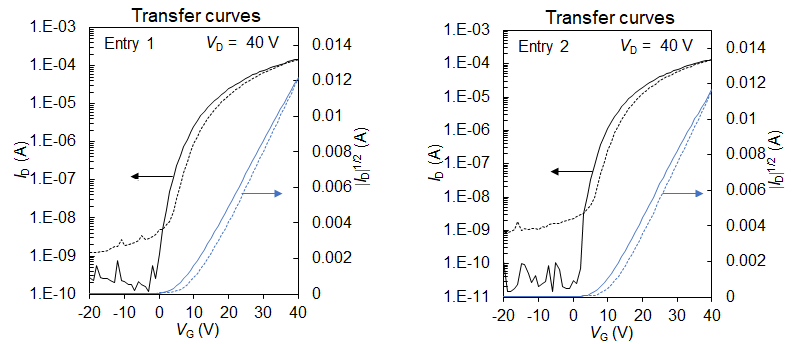

Figure. Transfer curves in the saturated region

Experimental details

Fabrication and evaluation of vacuum-deposited Fullerene C70 [F1233]-based OFETs

< Substrate>

< Self-Assembly Monolayer (SAM) Treatment>

< Vacuum Deposition>

< Device configuration>

< Evaluation condition>

< Substrate>

- HMDS-treated Si/SiO2 (thickness of SiO2: 200 nm)

- OTS-treated Si/SiO2 (thickness of SiO2: 200 nm)

< Self-Assembly Monolayer (SAM) Treatment>

- 1,1,1,3,3,3-Hexamethyldisilazane (HMDS) [H0089]

- Piranha etching (H2SO4:H2O2=4:1, 80ºC, 2h)

- Ultrasonication (Deionized water, Acetone, IPA, 10 min each)

- Exposure to vapor (IPA, 3 min)

- UV/O3 treatment (1 h)

- Immersion in HMDS (16 h, N2)

- Ultrasonication (Toluene, Acetone, IPA, 10 min each)

- n-Octyltrichlorosilane (OTS) [O0168]

- Piranha etching (H2SO4:H2O2=4:1, 80ºC, 2h)

- Ultrasonication (Deionized water, Acetone, IPA, 10 min each)

- Exposure to vapor (IPA, 3 min)

- UV/O3 treatment (1 h)

- Immersion in OTS solution (0.01 M toluene, 16 h, N2)

- Ultrasonication (Toluene, Acetone, IPA, 10 min each)

< Vacuum Deposition>

- Deposition rate of C70 [F1233] 0.2 Å/s (under a pressure of∼10−5 Pa)

- Substrate temperature during deposition: RT

- Deposition rate of Au: 0.2 Å/s (under a pressure of∼10−5 Pa)

< Device configuration>

- [n+-Si/SiO2 (200 nm) / C70 [F1233] (40 nm) / Au (40 nm)]

- Top-Contact Bottom-Gate Type (TCBG)

- Channel Length: 50 μm

- Channel width: 1.5 mm

< Evaluation condition>

- Under N2

- Field-effect mobilities (μ) were determined from the transfer curves in the saturation regime using the following equation:ID = (W/2L) μ Ci (VG − Vth)2

![Fullerene C70 [F1233]](/structure-300/F1233.jpg)