Maximum quantity allowed is 999

Please select the quantity

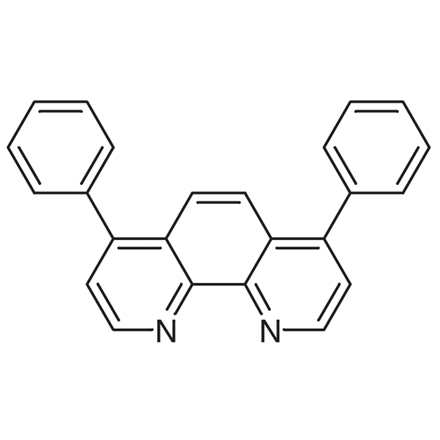

CAS RN: 1662-01-7 | Product Number: D0905

Bathophenanthroline

Purity: >99.0%(T)

Synonyms:

- 4,7-Diphenyl-1,10-phenanthroline

- Bphen

Product Documents:

* Please contact our distributors or

TCI

to order our products. The above prices do not include freight cost, customs, and other charges to the destination.

* The storage conditions are subject to change without notice.

| Product Number | D0905 |

| Purity / Analysis Method | >99.0%(T) |

| Molecular Formula / Molecular Weight | C24H16N2 = 332.41 |

| Physical State (20 deg.C) | Solid |

| Storage Temperature | Room Temperature (Recommended in a cool and dark place, <15°C) |

| Packaging and Container | 1G-Glass Bottle with Plastic Insert (View image) |

| CAS RN | 1662-01-7 |

| Reaxys Registry Number | 261048 |

| PubChem Substance ID | 87567505 |

| SDBS (AIST Spectral DB) | 3200 |

| MDL Number | MFCD00004976 |

Articles/Brochures

TCIMAIL

[Product Highlights] Copper/photoredox-catalyzed Decarboxylative sp3 C–N Coupling Reaction of N-Heteroaromatics[Research Articles] Arylation via C-H Activation using an Organocatalyst

Product Documents (Note: Some products will not have analytical charts available.)

Safety Data Sheet (SDS)

Please select Language.

The requested SDS is not available.

Please Contact Us for more information.

Specifications

C of A & Other Certificates

Please enter Lot Number

Incorrect Lot Number. Please input only the 4-5 alphanumeric characters before the hyphen.

Sample C of A

This is a sample C of A and may not represent a recently manufactured lot of the product.

A sample C of A for this product is not available at this time.

Analytical Charts

Please enter Lot Number

Incorrect Lot Number. Please input only the 4-5 alphanumeric characters before the hyphen.

The requested analytical chart is not available. Sorry for the inconvenience.

![(4,4'-Di-tert-butyl-2,2'-bipyridine)bis[3,5-difluoro-2-[5-trifluoromethyl-2-pyridinyl-κN)phenyl-κC]iridium(III) Hexafluorophosphate (4,4'-Di-tert-butyl-2,2'-bipyridine)bis[3,5-difluoro-2-[5-trifluoromethyl-2-pyridinyl-κN)phenyl-κC]iridium(III) Hexafluorophosphate](/medias/D5817.jpg?context=bWFzdGVyfHJvb3R8MjU2NzV8aW1hZ2UvanBlZ3xhRGxtTDJnMU5TODVNVEUyT0RJMk1qTTVNREEyTDBRMU9ERTNMbXB3Wnd8YmJkMWY4YTBjMWZkYTI1ZDRhZTVkNzRmZTk3YzM3N2FiZTYzNDUwNGJlNzEzMjJlODIzZDUyMzA0NWNiNThjMQ)