Maintenance Notice (4:00 AM November 1 - 9:30 AM November 1, 2025): This website is scheduled to be unavailable due to maintenance. We appreciate your patience and understanding.

Published TCIMAIL newest issue No.199

Maximum quantity allowed is 999

Surface modification by a self-assembled monolayer (SAM) is a useful technique in many research fields. Alkylsilane-based SAM agents have been particularly applied to organic field effect transistors (OFETs) with glass insulators, and contributed to the improvement of their performances.

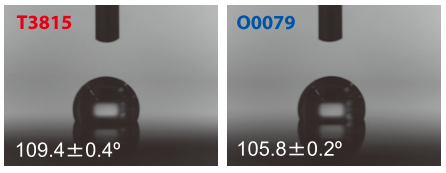

TCI has recently commercialized highly pure octadecyltrichlorosilane (ODTS) (>99%) [T3815]. This product contains extremely low levels of any branched and short alkylsilane impurities and could be readily used for the production of high-quality SAM films. We have demonstrated a correlation between the purity of ODTS and the performance of an OFET device using an in-house system, and revealed that OFET devices with the high-pure ODTS (>99%) [T3815] exhibited higher carrier mobilities than those with the conventional ODTS (>85%) [O0079].

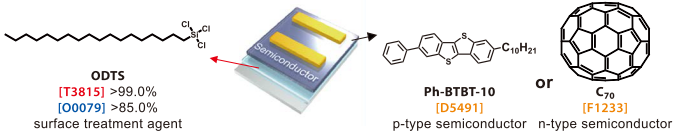

This product and the conventional product were evaluated as surface treatment agents in organic field effect transistor (OFET) devices using an in-house system. The high-pure ODTS (>99%) [T3815] and the conventional ODTS (>85%) [O0079] were treated on Si/SiO2 substrates respectively. The OFET devices were then fabricated on the ODTS-treated substrates using Ph-BTBT-10 [D5491], a high performance p-type organic semiconductor, and C70 [F1233], a typical n-type organic semiconductor, as the active layers.

Figure 1. Illustration for the structure of ODTS-treated OFET device

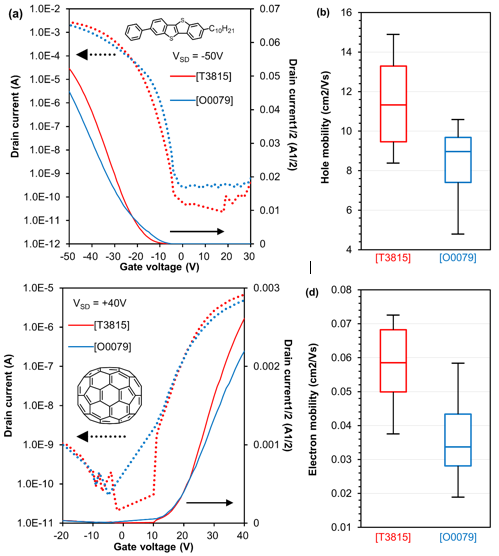

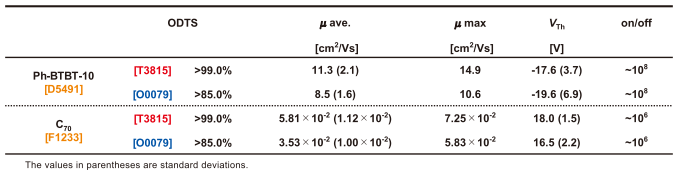

The performances of the OFET devices were summarized in Table 1 and Figure 2. The devices with the high-pure ODTS [T3815] exhibited higher career mobilities than those with the conventional ODTS for both Ph-BTBT-10-based and C70-based devices. The purification of the SAM agent would lead to the formation of the high-quality SAM film. It is expected to enhance the OFET mobility by using the high-pure ODTS [T3815].

Figure 2. Comparison of the OFET performance by the purity of ODTS,

transfer curves (a, c) and statistical distributions of carrier mobilities (b, d) for Ph-BTBT-10-based devices (a, b) and C70-based devices (c, d) respectively.

Table 1. Performances of ODTS-treated OFETs

Contact angles of water

n-Alkyltrichlorosilanes

Other-type surface treatment agent

Organic semiconductors