轻松扫码查看产品文档 | TCIMAIL No.197 已上新 | TCI试剂——品质可靠,值得信赖

订购方法?联系方式:021-67121386 / Sales-CN@TCIchemicals.com

Maximum quantity allowed is 999

请选择数量

CAS RN: 1296211-78-3 | 产品编码: E1127

4,4'-[1,2-Ethenediylbis(4,1-phenyleneiminocarbonyl)]bis(N-butyl-N,N-dimethylbenzenemethanaminium) Dichloride

![4,4'-[1,2-Ethenediylbis(4,1-phenyleneiminocarbonyl)]bis(N-butyl-N,N-dimethylbenzenemethanaminium) Dichloride No-Image](/medias/E1127.jpg?context=bWFzdGVyfHJvb3R8MzQ1MzJ8aW1hZ2UvanBlZ3xhRFl3TDJnMk1DODRPVEl4TmpJek5EazBOamcyTDBVeE1USTNMbXB3Wnd8ZGY1MjQ0ODE3YjM5MTg3MTRiNTVjYjUyZDM0OGY5ODUzMGFjMzYzNWQxNTE4Y2FmYmIxOTNhNDkyNTFhNmExOA)

* 点击“查询”可查看预计发货日期,仅供参考。

* 无具体发货日期的情况,如:显示“8个工作日后发货”,将在您订购日起的8个工作日后发货。

* 我们将以最优方式从上海/天津两大仓库发货。国内库存不足,需两周左右向日本总部调货。

* 对于可分装产品,11:30前的订单,当天发货;11:30后的订单,隔天发货。

* 如需大包装,请点击“大包装询价”按钮(对于某些产品我们无法提供大包装)。

* TCI会经常复审储藏条件以对其进行优化,请以在线目录为准,敬请留意。

* 更多信息,请联系营业部:021-67121386 / Sales-CN@TCIchemicals.com 。任何货期、规格或包装方面的需求,请联系我们 。

* 无具体发货日期的情况,如:显示“8个工作日后发货”,将在您订购日起的8个工作日后发货。

* 我们将以最优方式从上海/天津两大仓库发货。国内库存不足,需两周左右向日本总部调货。

* 对于可分装产品,11:30前的订单,当天发货;11:30后的订单,隔天发货。

* 如需大包装,请点击“大包装询价”按钮(对于某些产品我们无法提供大包装)。

* TCI会经常复审储藏条件以对其进行优化,请以在线目录为准,敬请留意。

* 更多信息,请联系营业部:021-67121386 / Sales-CN@TCIchemicals.com 。任何货期、规格或包装方面的需求,请联系我们 。

技术规格

| Appearance | White to Yellow to Green powder to crystal |

| Purity(Nonaqueous Titration) | min. 94.0 % |

物性(参考值)

GHS

| 象形图 |

|

| 信号词 | 警告 |

| 危险性说明 | H315 : 造成皮肤刺激。 H319 : 造成严重眼刺激。 |

| 防范说明 | P264 : 作业后彻底清洗皮肤。 P280 : 戴防护手套/戴防护眼罩/戴防护面具。 P302 + P352 : 如皮肤沾染:用水充分清洗。 P337 + P313 : 如仍觉眼刺激:求医/就诊。 P305 + P351 + P338 : 如进入眼睛:用水小心冲洗几分钟。如戴隐形眼镜并可方便地取出,取出隐形眼镜。继续冲洗。 P362+P364 : 脱掉沾污的衣服,清洗后方可重新使用。 P332 + P313 : 如发生皮肤刺激:求医/就诊。 |

相关法规

| 新化学物质备案回执号 | B1A232215852 |

运输信息

| 监管条件代码(*) |

应用

Single-Walled Carbon Nanotube (SWCNT) Dispersant

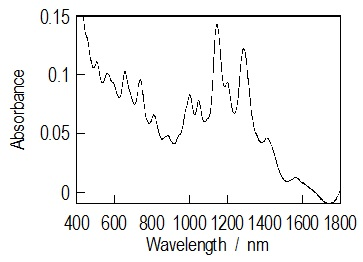

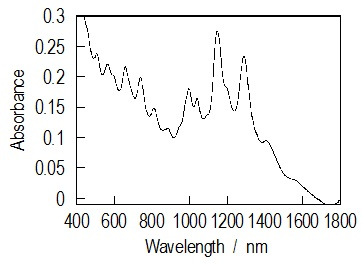

E1127 has strong interaction to the surface of single-walled carbon nanotube (SWCNT), and the positive charge on the stilbene core enables SWCNT to disperse in aqueous solution. UV irradiation makes closure of the stilbene moiety and elimination from the SWCNT surface which enables SWCNT to aggregate. After the aggregation, the dispersant can be easily removed by filtration, etc.

(1) Preparation of dispersions (Low power sonication)

3.6 mg of E1127 was dissolved in 3 mL of pure water (18.8 MΩ·cm, TOC < 3 ppb) or D2O using a glass vial (ca. 0.12 wt%). The solution was then sonicated (80 W, 35 kHz) at room temperature. Heating by a dryer is also a useful method for solvation. 1.96 mg of SWCNTs was added into the solution of E1127. The E1127/SWCNT mixture was sonicated (80 W, 35 kHz, 1 h) at room temperature. The black-colored dispersion was then centrifuged to remove impurities such as amorphous carbons and metal particles (28500 x g, at 22 °C, 3 hrs). Upper 70 % of supernatant was corrected as a well-dispersed SWCNT dispersion.

3.6 mg of E1127 was dissolved in 3 mL of pure water (18.8 MΩ·cm, TOC < 3 ppb) or D2O using a glass vial (ca. 0.12 wt%). The solution was then sonicated (80 W, 35 kHz) at room temperature. Heating by a dryer is also a useful method for solvation. 1.96 mg of SWCNTs was added into the solution of E1127. The E1127/SWCNT mixture was sonicated (80 W, 35 kHz, 1 h) at room temperature. The black-colored dispersion was then centrifuged to remove impurities such as amorphous carbons and metal particles (28500 x g, at 22 °C, 3 hrs). Upper 70 % of supernatant was corrected as a well-dispersed SWCNT dispersion.

(2) Preparation of dispersions (High power sonication)

10 mg of E1127 was dissolved in 20 mL of pure water (18.8 MΩ·cm, TOC < 3 ppb) or D2O using a glass vial (ca. 0.05 wt%). The solution was then sonicated (80 W, 35 kHz) at room temperature. Heating by a dryer is also a useful method for solvation. 7.0 mg of SWCNTs was added into the solution of E1127. The mixture was sonicated (80 W, 35 kHz, 1 h) at room temperature. Subsequently, the dispersion was subjected ultrasonication (60 W, 19 kHz, 4 hrs) at room temperature. The black-colored dispersion was then centrifuged to remove impurities such as amorphous carbons and metal particles (28500 x g, at 22 °C, 3 hrs). Upper 70 % of supernatant was corrected as a well-dispersed SWCNT dispersion.

10 mg of E1127 was dissolved in 20 mL of pure water (18.8 MΩ·cm, TOC < 3 ppb) or D2O using a glass vial (ca. 0.05 wt%). The solution was then sonicated (80 W, 35 kHz) at room temperature. Heating by a dryer is also a useful method for solvation. 7.0 mg of SWCNTs was added into the solution of E1127. The mixture was sonicated (80 W, 35 kHz, 1 h) at room temperature. Subsequently, the dispersion was subjected ultrasonication (60 W, 19 kHz, 4 hrs) at room temperature. The black-colored dispersion was then centrifuged to remove impurities such as amorphous carbons and metal particles (28500 x g, at 22 °C, 3 hrs). Upper 70 % of supernatant was corrected as a well-dispersed SWCNT dispersion.

(3) Photoirradiation and precipitation

A well-dispersed SWCNT dispersion was transferred to a dialysis tube (cutoff MW of 1000) to remove excess amount of E1127 from the dispersion. The tube filled with the dispersion of E1127/SWCNT system was put into a glass beaker with 3 L of pure water (18.8 MΩ·cm, TOC < 3 ppb) and was stirred overnight. The dialyzed dispersion was transferred into quartz cells and irradiated by an LED light source (365 nm, 100 mW/cm2) for several hours under magnetically stirring. After 3 hrs of light irradiation, precipitation of SWCNTs was completed for the dispersion treated with low power sonication. The SWCNT dispersion prepared using high power sonication took 7 hrs to recognize precipitation.

A well-dispersed SWCNT dispersion was transferred to a dialysis tube (cutoff MW of 1000) to remove excess amount of E1127 from the dispersion. The tube filled with the dispersion of E1127/SWCNT system was put into a glass beaker with 3 L of pure water (18.8 MΩ·cm, TOC < 3 ppb) and was stirred overnight. The dialyzed dispersion was transferred into quartz cells and irradiated by an LED light source (365 nm, 100 mW/cm2) for several hours under magnetically stirring. After 3 hrs of light irradiation, precipitation of SWCNTs was completed for the dispersion treated with low power sonication. The SWCNT dispersion prepared using high power sonication took 7 hrs to recognize precipitation.

References

- Photoinduced Dispersibility Tuning of Carbon Nanotubes by a Water-Soluble Stilbene as a Dispersant

- Effective Nondestructive Purification of Single-Walled Carbon Nanotubes Based on High-Speed Centrifugation with a Photochemically Removable Dispersant

- Y. Matsuzawa, M. Yoshida, H. Ohyama, H. Kato, Patent JP5552641.

参考文献

![4,4'-[1,2-Ethenediylbis(4,1-phenyleneiminocarbonyl)]bis(N-butyl-N,N-dimethylbenzenemethanaminium) Dichloride 4,4'-[1,2-Ethenediylbis(4,1-phenyleneiminocarbonyl)]bis(N-butyl-N,N-dimethylbenzenemethanaminium) Dichloride](/_ui/responsive/theme-tci/images/missing_product_zoom.jpg)