Published TCIMAIL newest issue No.196

Maximum quantity allowed is 999

Organotellurium-mediated radical Ppolymerization (TERP), developed by Yamago et al., is a type of controlled radical polymerization (CRP) which is also known as reversible-deactivation radical polymerization (RDRP) or living radical polymerization (LRP). Controlled radical polymerization techniques allow easy control of molecular weights, provides polymers with narrow molecular weight distributions, and enables the synthesis of specialized structure polymers such as block copolymers, star shaped polymers, and hyperbranched polymers. Organotellurium compounds are employed as chain transfer agents (CTAs) for TERP.

TERP is advantageous for the development of functional polymers due to its wide monomer functional groups scope and the possibility of end group transformations. In addition, TERP offers a broader range of monomers that can be controlled with the same chain transfer agent compared to reversible addition-fragmentation chain transfer (RAFT) polymerization. This advantage contributes to an improved design flexibility in block copolymer synthesis.

You can also see other CRP pages.

Products

Organotellurium Chain Transfer Agents (CTAs) for TERP

You can see the product category page related to TERP.

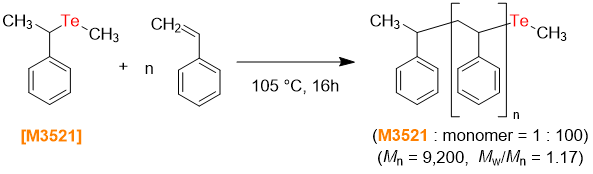

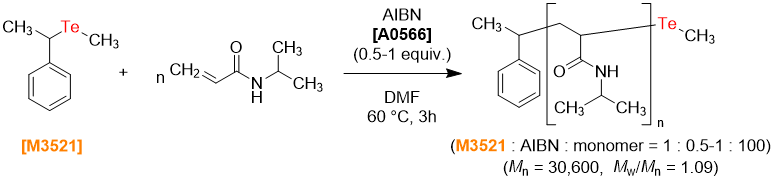

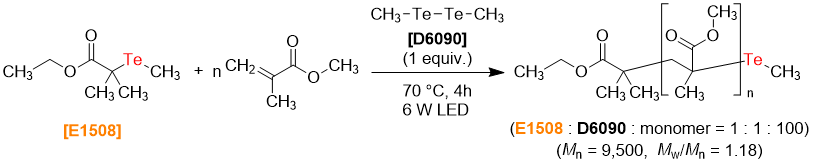

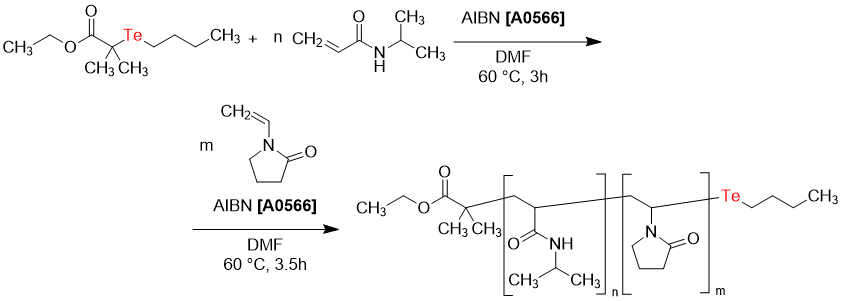

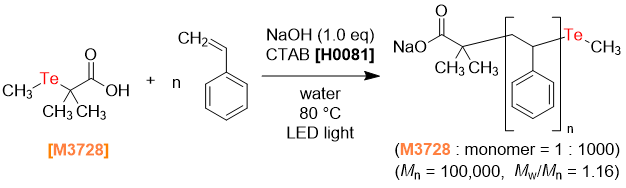

Reaction Examples of TERP

Polymerization by TERP can be carried out by thermal condition (Scheme 1), thermal condition with radical initiators (Scheme 2), or photoirradiation condition (Scheme 3). When applying the thermal condition with the addition of a radical initiator or the photoirradiation condition, polymerizations can proceed at lower temperatures compared to the thermal condition without radical initiators. In the case of methacrylate monomer polymerization, using only organotellurium chain transfer agents may lead to insufficient control of molecular weight distribution, so the addition of ditelluride compounds such as dimethyl ditelluride (Product No. D6090) or diphenyl ditelluride (Product No. D2718) is effective (Scheme 3). TERP is also effective for synthesizing block copolymers. For instance, the synthesis of diblock copolymers composed of N-isopropylacrylamide (NIPAAm), a more activated monomer (MAM), and N-vinylpyrrolidone (NVP), a less activated monomer (LAM), has been reported (Scheme 4). Additionally, synthesis of high molecular weight polystyrene via emulsion polymerization in an aqueous media using a chain transfer agent (Product No. M3728) having a carboxy group has also been reported (Scheme 5).6)

Scheme 1. Synthesis of polystyrene 3)

Scheme 2. Synthesis of poly(N-isopropylacrylamide) 3)

Scheme 3. Synthesis of poly(methyl methacrylate) 4)

Scheme 4. Synthesis of block copolymer 5)

Scheme 5. Synthesis of high molecular weight polystyrene via emulsion polymerization 5)

Product Brochure

Related Product Category Pages

References

- 1) Precision Polymer Synthesis by Degenerative Transfer Controlled/Living Radical Polymerization Using Organotellurium, Organostibine, and Organobismuthine Chain-Transfer Agents

- 2) Photoactivation of Organotellurium Compounds in Precision Polymer Synthesis: Controlled Radical Polymerization and Radical Coupling Reactions

- 3) Development of organotellurium-mediated and organostibine-mediated living radical polymerization reactions

- 4) Organotellurium-mediated living radical polymerization under photoirradiation by a low-intensity light-emitting diode

- 5) Thermo-Responsive Diblock Copolymers of Poly(N-isopropylacrylamide) and Poly(N-vinyl-2-pyrroridone) Synthesized via Organotellurium-Mediated Controlled Radical Polymerization (TERP)

- 6) Controlled Synthesis of High-Molecular-Weight Polystyrene and Its Block Copolymers by Emulsion Organotellurium-Mediated Radical Polymerization